Description

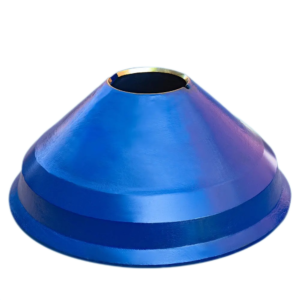

CMWT has applied the same engineering problem-solving to crushers which has proven so effective on Gyratory crushers and Cone crushers.

We went into the field and studied the many areas for potential improvement: poor nip of feed material, excessive wear in the lower crushing chamber, poor throughput from partially worn parts, excessive wear metal discard costs and problems with uneven or localized wear.

We’re the leader in gyratory crusher liner innovations, and it’s a rare crusher which cannot show significant gains in production and wear life from a Columbia analysis and improved wear parts.