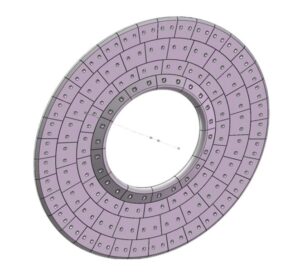

Description

The third generation of ultra-thin wear-resistant lining board is used for the ball mill lining board, the use of multiple alloys and dispersed ceramic particles, so that the lining board has excellent wear resistance and high strength, high toughness excellent performance, and through the innovative heat treatment process, effectively solve the dispersion of ceramic particles in the heat treatment process or affect the subsequent use of quality problems. At the same time, a series of high-efficiency ball milling comprehensive energy-saving technologies is adopted to further improve the grinding efficiency of the lining board. In the design of the waveform parameters of the liner, the equivalent wear factor of the liner is fully considered, which effectively avoids the effect of the waveform of the liner on the operating conditions due to wear; According to the actual production requirements, choose the appropriate alloy and ceramic material ratio, the density is adjustable, the weight is light, can reduce the thickness of the liner more than half, increase the space inside the ball mill more than 3%, for the mill to achieve economic operation provides a prerequisite.